Quality Testing

Quality Test House

APVM Electronics Test lab has a long engineering experience in electronic parts screening, qualification, and in-house test fixtures allowing us to provide the best components testing in a timely manner. We perform counterfeit part analysis on all types of electrical, electronic, and electromechanical components. Our solutions approach of keeping complete capabilities in-house allows us to better control program costs and minimize schedule delays.

External Visual Inspection/Microscopy/Magnifying

Our Visual Inspection test involves inspecting of electronic components under a microscope to determine if a component or product has been altered from its original state. During this process a device may show signs of non conformance or inconsistencies that help determine if a component or product has been used or if a device is new and original. This process is normally performed by our in-house quality team. This process is a non-destructive and devices can be used afterwards.

Acetone Testing

Most plastic integrated circuits have cavities purposefully made during the mold process. Some of them are pin one or other designations for use in part placement, but others are just part of the plastic mold process. Mold cavities should be clean, according to the manufacturers we have spoken to. Examining these indents is our number one way of detecting counterfeit components. The counterfeiters have a very difficult time keeping the indents clean and consistent during their refinishing process. The pictures to follow are examples of what we have received in our warehouse and a small explanation of our observation follows.

Dimension Verification

Key Functional Testing

Functional testers typically use a computer that is connected to test points or a test-probe point in order to perform FCT. We determine if the boards pass or fail based on whether or not the test results meet the specified requirements by operating the software or firmware.Functional testing is enabled by testing software, often referred to as firmware, and testing instruments such as digital multimeters, input/output PCBs, communication ports.

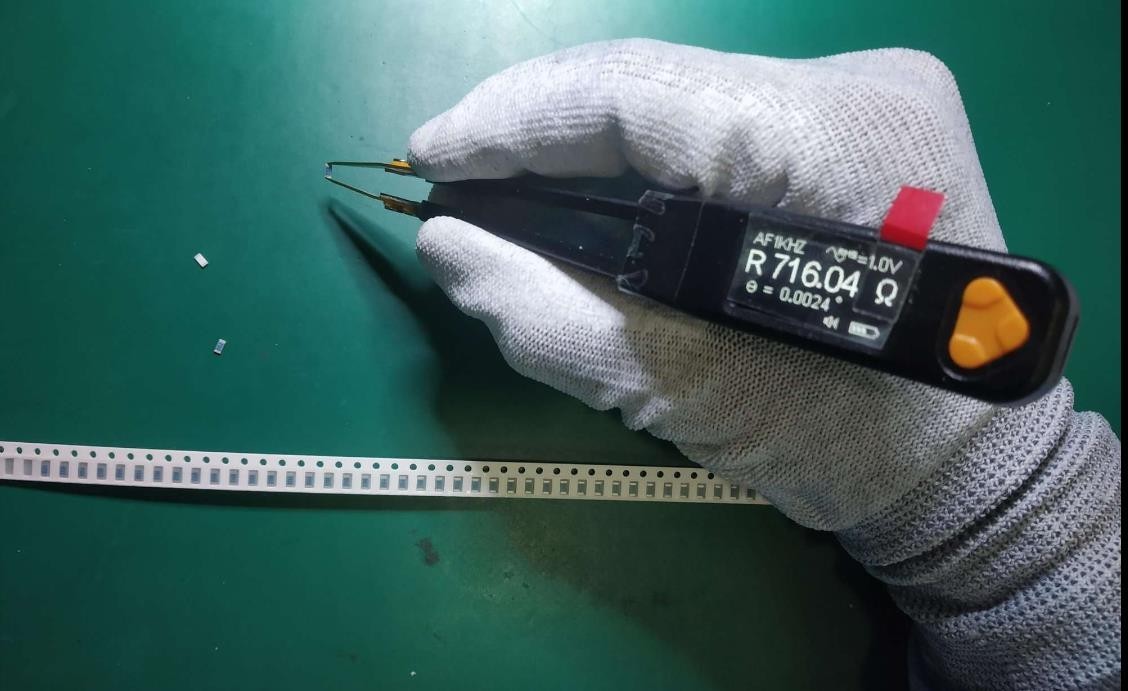

Electrical Testing/DC Testing

DC test parameters are typically specified in Volts, Amps or Ohms. DC Testing insures proper device operation - acceptable power consumption, basic functionality, verifies data sheet parameters, etc. It provides a reasonable Cost/Benefit trade-off when at least one data sheet parameter needs to be measured to verify functionality.

Documentation And Packaging Inspection

The majority of product we receive is improperly packaged, so they need to put into proper carriers, baked, and dry-packed prior to shipment. We drop-ship each order to get your customers product faster and with less expense. Why transfer product between, and try to manage, multiple partners? APVM provides a turn-key solution.